If you are going to pick the best concrete mixer for a particular application, you must consider these variables: area of the development site, the measure of cement required and the development plan.

In the event that you are going to pick the best solid blender for a particular application, you must consider these elements: area of the development site, the measure of cement required and the development plan.

There are two primary classifications of mixer: forced type concrete mixer and self-loading concrete mixer.

Forced Type Concrete Mixer

Forced type concrete mixer machine can be isolated into two sorts. One is twin shaft solid blender and the other is planetary solid blender. Their working standards are very much alike. They both blend concrete through the revolution of the pole. In the meantime the edges joined to the pole are much the same as numerous hands to blend the cement more homogeneous. The distinction between them is that twin shaft solid blender has two level shafts while the planetary solid blender has one vertical solid blender. Both are cement concrete mixer machine, as a part of construction machinery, helping in construction.

1. Twin Shaft Concrete Mixer

On the other viewpoint, the blending edges of twin even shaft concrete mixer pivot contrarily. The edges blend materials more than once to make the materials more homogeneous. In this furious procedure of turn, it spared considerably more time. Along these lines, the twin shaft solid blender is included by high proficiency and low time intensive. This solid blender is generally utilized as a part of the entire world for it is savvier.

2. Planetary Concrete Mixer

On the other hand, for planetary concrete mixer, the two gatherings of blending edges blend materials advantages and disadvantages. The upset and revolution pace of the razor sharp edges give the blender a high yield without bringing about the isolation of materials with distinctive grain size and weight. The development of the material inside the trough is smooth and nonstop. This mixer is highlighted by high effectiveness, great and low upkeep. The solid it delivers is with higher quality. Be that as it may, the cost of it is exceptionally extravagant.

How to get consistent quality in cement

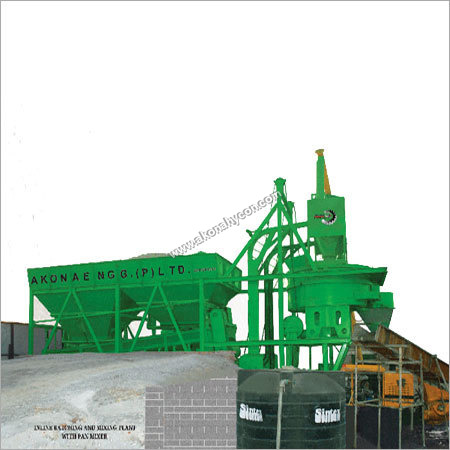

To get the consistent quality of cement concrete, all the ingredients like cement, sand, metal, water and additive chemicals are measured and mixed per batch in Cement Concrete Mixer Machine. This equipment has the properties of extended shaft end, durable hydraulic pump, multiple tubes for water spraying and high performance taper mixing arm. Owing to these properties, it produces uniform quality cement always.

In the event that you are going to pick the best solid blender for a particular application, you must consider these elements: area of the development site, the measure of cement required and the development plan.

There are two primary classifications of mixer: forced type concrete mixer and self-loading concrete mixer.

Forced Type Concrete Mixer

Forced type concrete mixer machine can be isolated into two sorts. One is twin shaft solid blender and the other is planetary solid blender. Their working standards are very much alike. They both blend concrete through the revolution of the pole. In the meantime the edges joined to the pole are much the same as numerous hands to blend the cement more homogeneous. The distinction between them is that twin shaft solid blender has two level shafts while the planetary solid blender has one vertical solid blender. Both are cement concrete mixer machine, as a part of construction machinery, helping in construction.

1. Twin Shaft Concrete Mixer

On the other viewpoint, the blending edges of twin even shaft concrete mixer pivot contrarily. The edges blend materials more than once to make the materials more homogeneous. In this furious procedure of turn, it spared considerably more time. Along these lines, the twin shaft solid blender is included by high proficiency and low time intensive. This solid blender is generally utilized as a part of the entire world for it is savvier.

2. Planetary Concrete Mixer

On the other hand, for planetary concrete mixer, the two gatherings of blending edges blend materials advantages and disadvantages. The upset and revolution pace of the razor sharp edges give the blender a high yield without bringing about the isolation of materials with distinctive grain size and weight. The development of the material inside the trough is smooth and nonstop. This mixer is highlighted by high effectiveness, great and low upkeep. The solid it delivers is with higher quality. Be that as it may, the cost of it is exceptionally extravagant.

How to get consistent quality in cement

To get the consistent quality of cement concrete, all the ingredients like cement, sand, metal, water and additive chemicals are measured and mixed per batch in Cement Concrete Mixer Machine. This equipment has the properties of extended shaft end, durable hydraulic pump, multiple tubes for water spraying and high performance taper mixing arm. Owing to these properties, it produces uniform quality cement always.